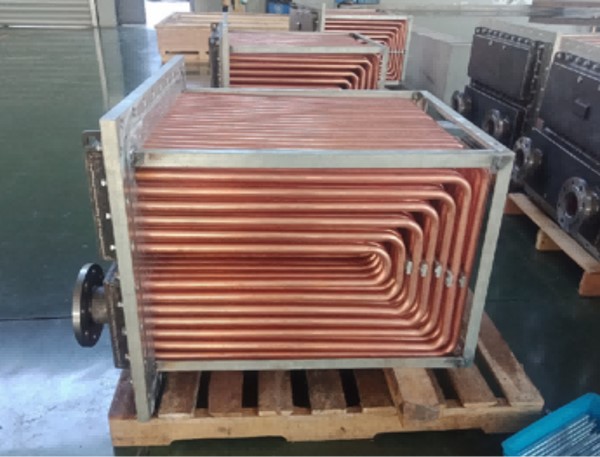

BOX COOLER

- Box coolers are often installed in sea cabinets on the side of the ship to save space in the engine room. The U-shaped tube bundle inside perfectly lifts the entire off-board secondary cooling water circuit, which is less susceptible to corrosion and scaling than other solutions.

- Our box coolers are manufactured with corrosion-resistant materials. This heat exchanger type is virtually maintenance-free and can be customized for all operating conditions and temperatures.

- Box coolers can be used for a variety of cooling jobs in the following applications: hydroelectric units, ships, compressors, chemical, engine, marine, and other industries.

Table of Contents

- Download this page as a PDF

To save you time, we have also prepared a PDF version containing all the contents of this page.

Why choose Jedheatexchanger.com?

We are a company that values customer satisfaction. We have been manufacturing and supplying quality coolers to meet all your needs.

Jedheatexchanger has over 20 years of experience in this field.

You can come to the factory and inspect our products, equipment, instruments, management, materials, and shop floor. Contact us! We can arrange an open inspection for you. Due to COVID-19, we do not currently promote on-site inspections, and we can provide you with a video.

- We are ISO quality and environmental certified.

- We will ensure that we provide you with only excellent heat exchange performance.

- Our heat exchangers are very durable because of the careful materials and strong after-sales service.

- As a brand, we are sincere in all our dealings.

Hot products according to our clients feedback

JEDHEATEXCHANGER not only wholesales a certain type of heat exchanger, but also manufactures all the bearing oil coolers you could ever think and never think of. Here are some of our customers’ favorite products.

Advantages of box coolers

No secondary cooling water piping outside the ship

Therefore, there is no need for cooling water pumps, filters, pipelines, and other wearing parts, and it is less likely to corrode and attach to sea life.

Energy saving (secondary pump)

Compared with traditional cooling water systems, it can save 15,000 liters of oil by running 5,000 hours per year.

Flexible operation

Ideal for operation in icy, narrow, muddy, or polluted areas.

Easy to install

Can be welded to the bottom door plate of the ship, so that the hose bundle does not have to be removed for internal inspection and testing.

Estimated wholesale price

Payments made to Jedheatexchanger products are secure, and the following is a summary of the costs you will incur.

Program Design

Free of charge! We have a separate team that can produce solutions, drawings, improvements, and upgrades according to your requirements.

Testing

Including air tightness test, weld PT, full-size inspection, oil cooler performance test, etc.

Production Processing

Materials, accessories, assembly, machining, production, workpieces, welding, painting, and a host of other costs and time are required.

Shipping Fee

This is the amount you will know to get the product from the factory to your doorstep. We provides you with any kind of convenience.

Estimated manufacturing and shipping times

We work quickly. With more and more customers approaching us, we have no other choice but to prioritize speed. Let’s take a look at the entire process of manufacturing and shipping.

1. Solution Design

The team will discuss with you the program, performance, cooling range, heat exchange requirements, parameters to the final satisfaction.

2. Production Processing

The product will take 7-50 working days according to the process of the material, parts processing, cleaning, assembling, welding, painting, packaging, etc.

3. Inspection and testing time for all products

These tests and reports require time: gas tightness testing, weld PT, full size inspection, oil cooler performance, and pressure testing.

4. Sea and land transportation time

You can choose to ship your goods by sea, air, land or rail, and we will do a good job of reinforcing the packaging for safe transport.

Is It Good As Other coolers? Things you Need to Know

To save you from worries, here are some facts you need to know about our heat exchanger supplies:

What is the difference between box type cooler and general plate type cooling?

The box cooler is installed directly into the subsea door and the outboard seawater for heat exchange without the need for a seawater pump. The plate cooling is powered by the seawater pump for heat exchange.

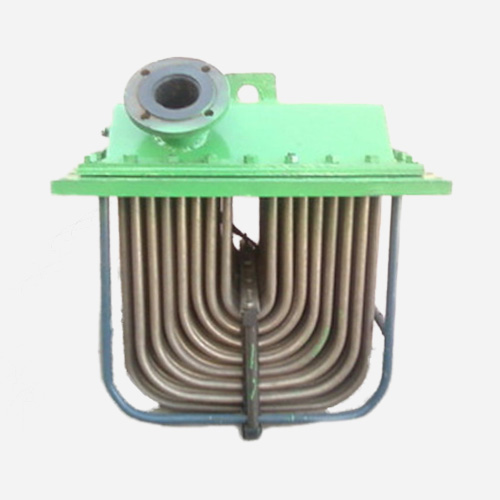

Why are there box coolers with a tubular shape?

We believe that the main nature of box cooler is to cool by inserting or immersing the liquid, so in addition to the box type, there are shell tube and coil type can be common.

Why are there not many box coolers on the market?

Because we customize them directly to ship manufacturers or hydroelectric unit projects. The sales channel is very direct, and the quality of the product is very good rarely generating maintenance problems.

What are the standard sizes of your wholesale coolers?

There are no standard sizes. We manufacture conventional tubular coolers on a permanent basis and accept your custom cooler orders.

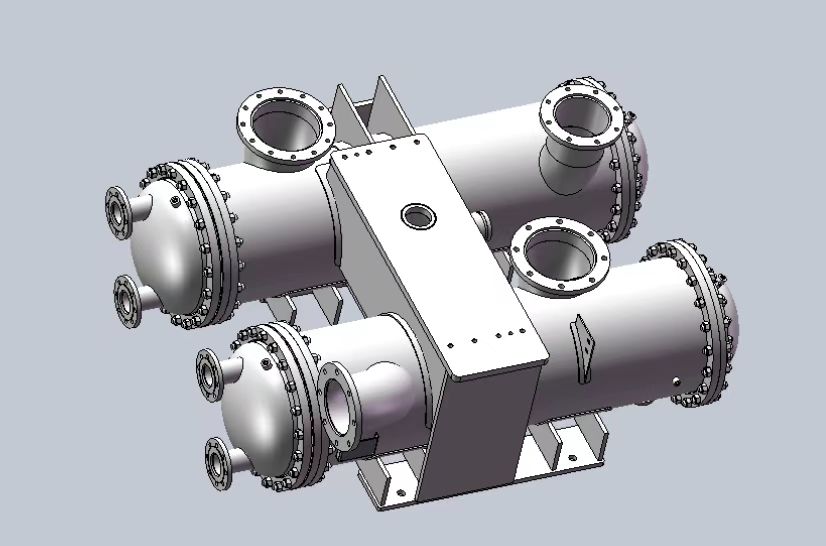

Products Related To Box Cooler

We have a large selection of heat exchangers for various applications. With us, you can order your products according to your own drawings and specifications or you can choose from our large and wide standard selection. In addition, our short lead times and good logistics make us an efficient and reliable partner.

WE'D LOVE TO HEAR FROM YOU

Customizing Your Heat Exchanger

If the following information is provided, you will receive an accurate cooling system solution within 24 hours. If you do not have a detailed plan at the moment, we are also willing to help you with our experience.